St Anne’s Catholic School in Kialla near Shepparton has been in the planning since the site was purchased in 2014 with a desire to create a modern school embracing the latest best practice design and construction of learning spaces.

Used in this project

- Products

- Steeline Lokdek 680 (ST35)

- Steeline Steel Span 700 (ST29)

- Materials

- COLORBOND® steel - Classic finish

- Colours

-

-

-

-

St Anne’s Catholic School in Kialla near Shepparton has been in the planning since the site was purchased in 2014 with a desire to create a modern school embracing the latest best practice design and construction of learning spaces.

Ken Woodman from No. 42 Architects, who specialises in developing learning facilities said, “The design intent was to provide a learning environment that fully supports the College’s student-centred social constructivist pedagogy while connecting the building to the local community”.

“The built outcome will be home to a future community of learners in a place that embodies the College’s motto of Faith, Wisdom and Learning,” Mr Woodman said, “I was really reassured when the Steeline team came on board. The workmanship that they put into the job was a work of art”.

This new school has been designed to be able to be built in stages so that the facilities are increased in line with the projected growth in the school’s student population. In all, there will be six stages of an extruded building with the first structure completed in July 2018.

“Steel cladding was specified due to its durability, it is available in the range of desired colours, doesn’t need to be painted, and for potential re-use when we start to develop the subsequent phases and the new structure are added to the site.” Mr Woodman said.

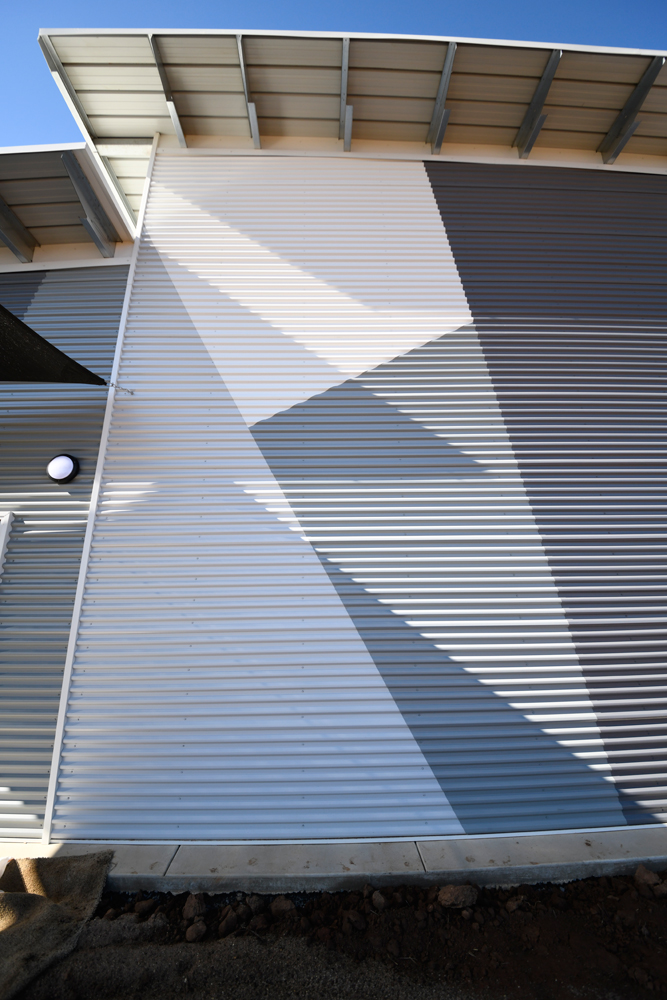

The external design for the building was based on the organic shapes of the local long neck turtle which is the totem of the local indigenous peoples. The wall pattern was designed around the hexagon shapes found on the turtle’s shell and the organic shapes of the building reference the turtle’s shell which also forms a protective shell roof for students and faculty.

Steeline commenced work on this challenging building in November 2017 with the installation of 1982m2 of Steeline Lokdek roof and 513m2 of Fielders ARAMAX® cladding the building's awnings both using COLORBOND® steel Surfmist® in a Classic finish. The 937m2 internal ceilings were clad using Perforated Steelspan steel also using COLORBOND® steel Surfmist®.

Finally, the 850m2 exterior walls of the building and external soffit linings were clad with a challenging multicolured design using Steeline Steelspan in a combination of COLORBOND® steel colours Basalt®, Shale Grey™, Surfmist® and Windspray®, all in a Classic finish.

Jay Bruce, the Project Manager, for the main contractor, Moretto Building said, “The Steeline guys were great and I have never been on site where the architect comes up to shake a roofer’s hand to thank them for the quality of work”.

Whilst it is not a large structure or project for Steeline, due to the precise nature of the design and to achieve this complex design puzzle, each sheet of cladding was different dimensions and had to be hand cut. The Steeline team had to not only deliver on the aesthetics but also to make sure that the building was watertight and would stand the test of time. This first stage of the building was completed after 4,370 man hours from the Steeline team.

Travis Ryan, Steeline Branch Manager for Shepparton explained, “whilst it was a challenging project, everyone was thrilled with the outcome and the project was completed on time and on budget”.

Dom Poppa, St Anne’s Foundation Principal, was thrilled with the outcome “Everyone who comes to the school is so complimentary on the look of the school, and whilst we are not yet open, the sessions we have held inside have been fantastic. The space is everything we wanted. We can’t wait to start the next phases of this building”.